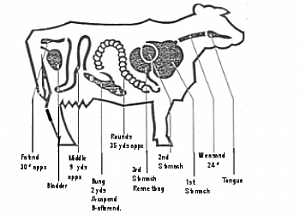

Beef casings for natural casings are mainly produced from the rounds (35 yards), the middles (9 yards) and the

beef bungs (2 yards).

The calibre (diameter) of natural beef casings can range from 36 mm to 50 mm for rounds, 45 mm to 65 mm for middles

and 75 mm to 130 mm for beef bungs.

Like hog casings the narrower size tends to be more valuable in beef casings.

Beef casings are not generally graded as a, A/B or C but emphasis is placed upon lack of holes and blemishes as being

of better quality.

Weasands, beef fat ends and beef bladders are also used in the production of some types of sausage.

Beef casings are predominantly used for the production of salami or continental type sausage.

THE SAUSAGE

Beef casings are used to make the following types of sausage:

Black pudding, Haggis (traditionally sheep's stomach)

Dry and cooked salami, Veal sausage, Bologna liver sausage

and Polish sausage.

CHARACTERISTICS

Most sausage made with beef casings have the same characteristic traditional curved shape.

OTHER PRODUCTS

SURGICAL SUTURES / RACKET STRINGS / MUSIC STRINGS

The above products are not made from the actual beef intestine but with what is known as beef serosa which is the

membrane from the inside of the beef intestine (rounds).

As with sheep casings the initial process in manufacturing these strings is to split the beef intestine lengthwise into

ribbons.

The serosa (membrane) is then separated from the actual beef intestine. The serosa whilst very thin in texture is

incredibly strong and flexible.

Beef serosa has proven to be an excellent substitute for the production of sutures, racket strings and music strings

having the same characteristics of strength and flexibility as needed for racket strings and the same degradability

as required for suture use.

GOLDBEATER SKINS

The outer membrane of beef intestine had traditionally been used in reducing gold into 1 mm thick

leaves but these days this description is more likely to refer to the product used in the manufacture

of temperature and humidity recorders / controllers.

These goldbeater skins are produced from the membrane from the inside of the bung.

This is cut to give a flat piece of which four pieces are soaked, layered together and placed

on a frame to dry.

The dried membrane (measuring 9 ins x 7 ins) resembles parchment or vellum.

The piece is cut into strips (1 in x 6 ins) and a strip is attached to a spring and measuring

device within a hygrometer.

The goldbeater skin has a very sensitive hygroscopic property which causes it to contract or

expand with any variation in humidity in the atmosphere. These recorders / controllers are placed in areas where

humidity control is of critical importance.